You have probably been stuck in a vehicle in the winter with a malfunctioning heating system or experienced a car battery refusing to start. Did you know that can happen to your home when the temperature drops? There are many common winter problems people experience with their heating, ventilation, and air conditioning (HVAC) systems when it gets below zero outside.

Why is my air conditioner so loud?

If your air conditioner is loud, don’t ignore it, especially if instead of a loud hum there is a loud clunking and chunking. A loud air conditioner signals that it is not working properly. When an air conditioner isn’t working properly it is either working too hard and driving up your energy bill or not running enough and hardly cooling

What are the Cons of a Window A/C Unit?

Are you burning up or being bogged down in the heat and humidity this summer? Before you rush out to Home Depot or Walmart, buy an air conditioning unit, and plunk it in your window, take a moment to consider the pros and cons of that purchase. Pros: They are relatively inexpensive to buy. Unless you are putting one

Are Your AC Costs Through the Roof?

Are Your AC Costs Through the Roof? Kiddie pools and cold drinks help keep you cool through the heat wave, but the best option to beat the heat is to turn on the air conditioner. To cook, relax, and sleep more comfortably in your home this summer, the air conditioning unit will be your next best friend. Although you want

Common Air Conditioning Problems

Air conditioning is a Minnesota must-have for the summer months. Your air conditioner doesn’t simply cool the room, it cools the temperature while also removing any moisture or humidity as well. In the Land of 10,000 Lakes, summer humidity is a real concern. When your A/C system is on the fritz, it’s not just a matter of discomfort; it can

Air Conditioner Tune-ups for the Upcoming Summer

We’re all beyond tired of the snow and cold weather! Bring on the warm air, sandals, and backyard barbeques! Yes, you might be ready for the summer but, is your air conditioner ready too? Getting a tune-up for your A/C unit is just as important for the summer as putting on sun-block. Both precautionary measures will ensure you have the

Frequently Asked Questions about Air Conditioners

It can be hard to find answers to your air conditioning questions when every company has their own agenda. We want to make sure you have access to all the information you need to ensure you get exactly what you’re looking for, in equipment and information. We’ve compiled a list of the most common questions across the board in an

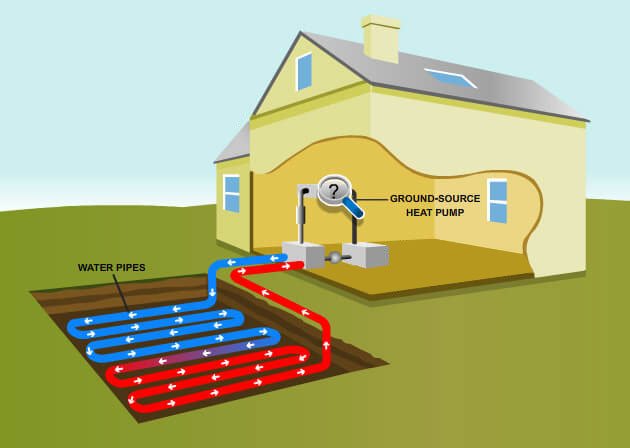

The Advantages and Disadvantages of Geothermal Heating and Cooling Systems

Geothermal heating is an energy source that controls the temperature of your home or business. The system requires drilling holes a few feet into the ground where the temperature is consistent all year. The technology draws water on a loop from the hole and heats or cools your environment. While it seems like a great way to save on electricity

Plumbing & HVAC Installation At St. Joseph Millstream Park Pavilion

[av_heading tag=’h1′ padding=’20’ heading=’Plumbing & HVAC Installation At St. Joseph Millstream Park Pavilion’ color=” style=” custom_font=” size=” subheading_active=” subheading_size=’15’ custom_class=”][/av_heading] [av_textblock size=” font_color=” color=” custom_class=”] Our team at Finken was lucky enough to be able to work with the City of St. Joseph on the new Millstream Park Pavilion! City of St. Joseph Public Works Director Terry Thene said the

It’s Getting HOT!

[av_textblock size=” font_color=” color=”] Will your Air Conditioner Keep You Cool This Summer? 5 Tips to Keep Your A/C chillin’ One of the best feelings on a hot, humid summer day is coming inside to a cool, fresh air conditioned house or office. Give your air conditioner a fighting chance to survive this summer by doing these simple air conditioner

- Page 1 of 2

- 1

- 2